Controller performance specifications

Controller performance specifications, such as settling time and overshoot, play a crucial role in evaluating and designing control systems.

1.Settling Time: Settling time is the time it takes for the controlled output to reach and remain within a certain tolerance of the desired set-point after a disturbance or reference change. In other words, it measures how quickly the control system stabilizes and maintains the desired value. A shorter settling time indicates a faster response and better dynamic performance of the controller. Achieving a low settling time is particularly important in systems where quick and accurate responses are required, such as in high-speed manufacturing processes or critical control applications.

2.Overshoot: Overshoot refers to the extent by which the controlled output exceeds the desired set-point before eventually settling down. It is expressed as a percentage of the set point value. An overshoot occurs when the control system response oscillates around the set-point before converging to the desired value. In well-designed control systems, overshoot is typically minimized to avoid instability, oscillations, or potential damage to the system or the controlled process. High overshoot values can be detrimental in applications where stability and precision are essential, such as in control systems for chemical reactors, aircraft, or robotics.

In summary, settling time and overshoot are performance metrics that assess the dynamic behavior of a control system. A shorter settling time indicates a quicker response to disturbances, while minimizing overshoot helps maintain stability and accuracy. These specifications are critical in ensuring control system efficiency, stability, and suitability for specific applications. Engineers use these parameters to optimize controller design and achieve desired control objectives.

Matlab Control System Designer App References:

Getting Started with the Matlab Control System Designer

Explanation Video of Control System Design with the Control System Designer App

Controller Performance Requirements

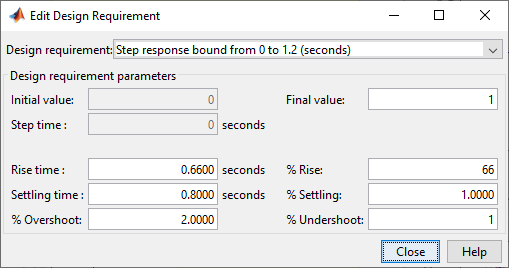

•Settling time < 1s

•Overshoot < 2%

Figure 24: Controller Performance Requirements Set in the Control System Designer App

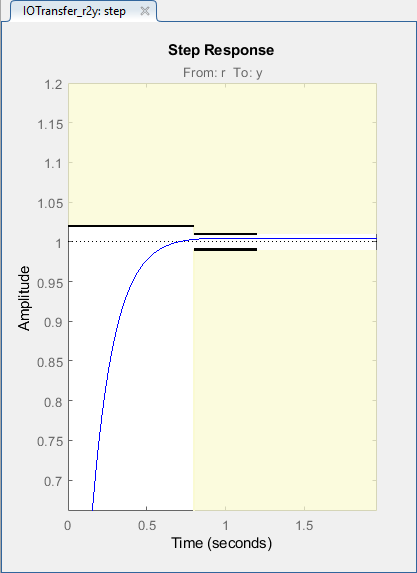

Line should be within the boundaries of highlighted white color area as Figure 25.

Figure 25: Step Response Graph with Marked System Design Requirements

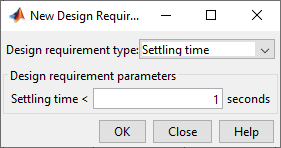

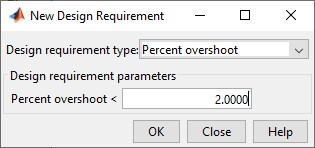

In the MATLAB Control System Designer, the root locus plot provides valuable insights into the stability and performance characteristics of control systems. To improve the design process, you can add new performance requirements to the root locus plot by right-clicking on the graph's white space. By specifying overshoot percentage and settling time requirements, you can set explicit criteria for the system's transient response.

Figure 26: Adding Settling Time Design Requirement in the Root Locus Graph

Figure 27: Adding Precent Overshoot Design Requirement in the Root Locus Graph

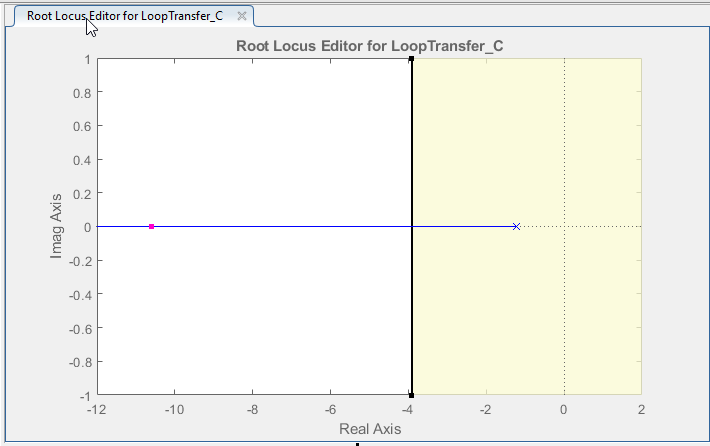

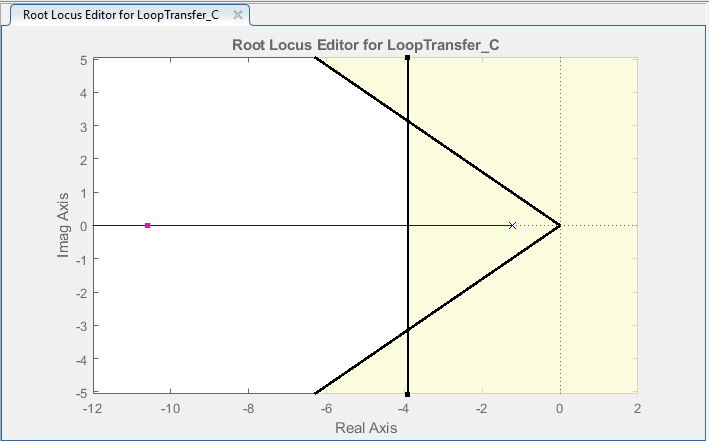

Once you set these requirements, the root locus plot will visually indicate the regions that satisfy the specified overshoot and settling time criteria. These regions will be highlighted in white. Conversely, the areas that do not meet the requirements will be colored in yellow.

This graphical representation allows you to identify the regions in the complex plane that fulfill the desired performance specifications.

Figure 28: Display of Added Settling Time Design Requirement on the Root Locus Graph

Figure 29: Display of Added Precent Overshoot Design Requirement on the Root Locus Graph

By manipulating the positions of poles on the root locus plot, the control system designer can assess the impact on overshoot and settling time in real-time. The goal is to find the optimal pole locations that strike a balance between achieving the desired performance and maintaining system stability.

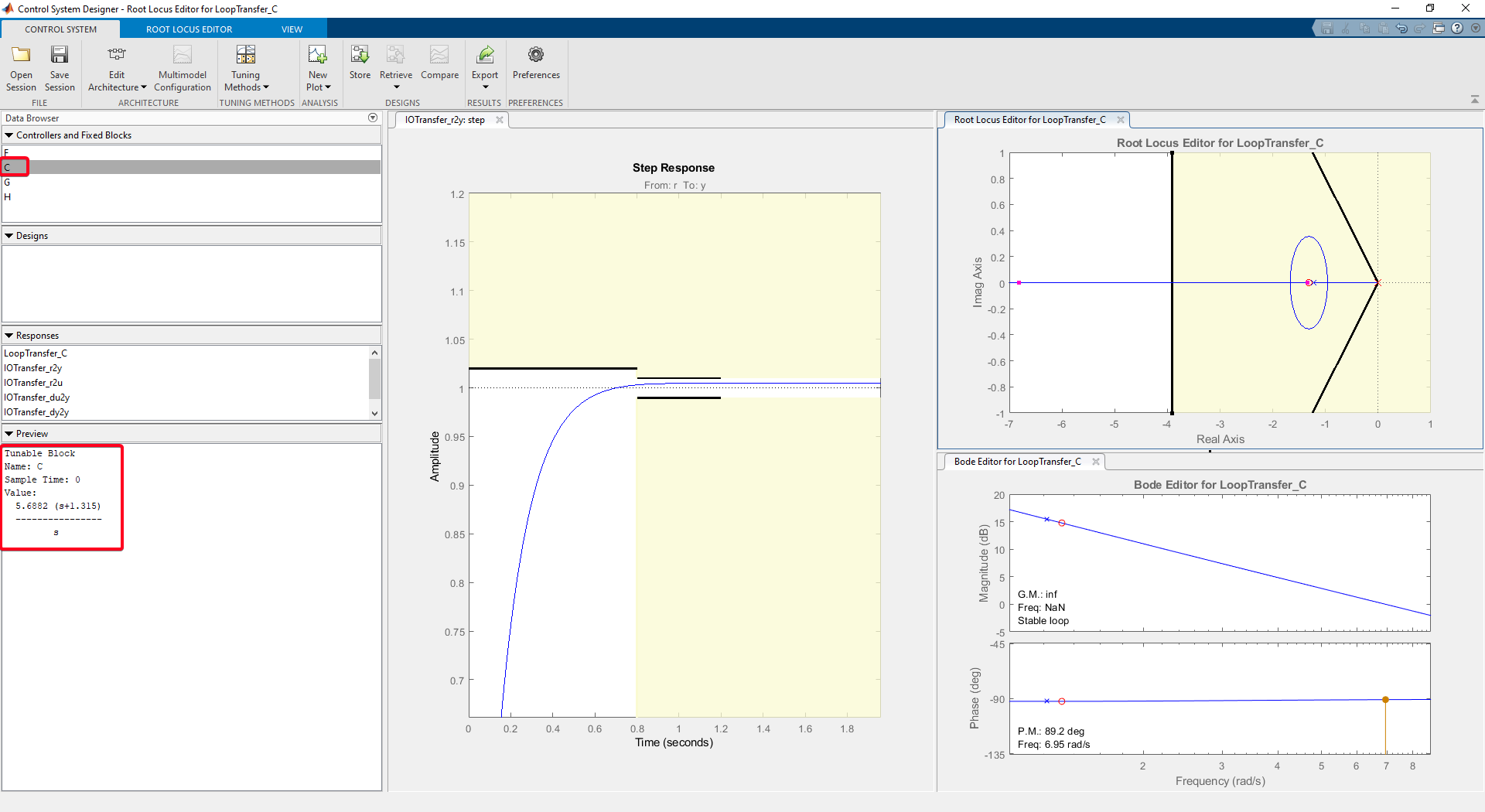

Final Controller design

Controller System Designer file: rc_ControlSystemDesignerSession.mat

Figure 30: Final Controller Design Achieved Through Optimization

Final Controller design Characteristic

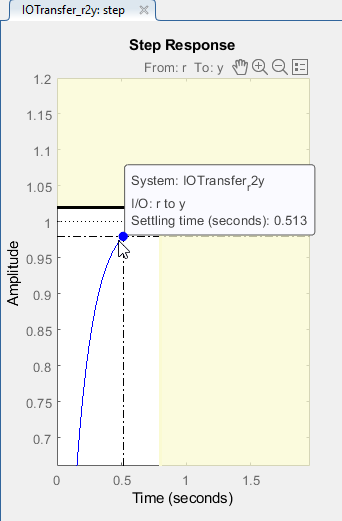

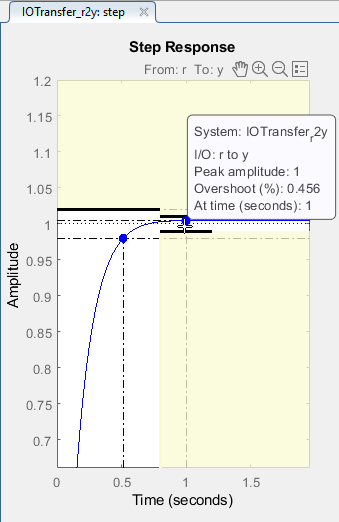

•Settling time (seconds): 0.513

•Overshoot (%): 0.456

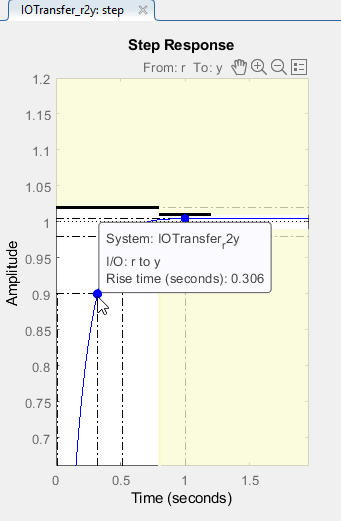

•Rise time (seconds): 0.306

Figure 31: Settling Time Characteristic of Final Controller Design Reflected in the Step Response Graph

Figure 32: Overshoot Characteristic of Final Controller Design Reflected in the Step Response Graph

Figure 33: Rise Time Characteristic of Final Controller Design Reflected in the Step Response Graph

Evaluate Designed Controller Performance

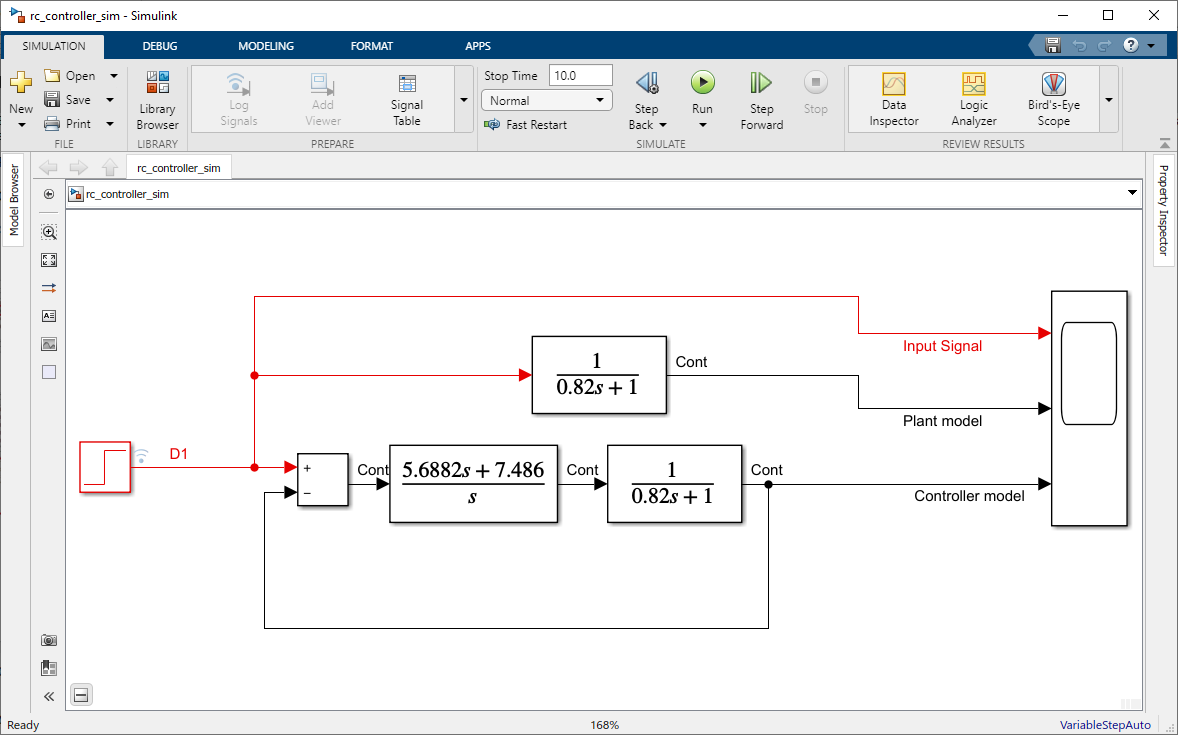

Step 1: Get Designed Controller Transfer Function

Step 2: Create the Simulink model

Simulink Model: rc_controller_sim.slx

Use following blocks:

•For Input : Use Step block

•To create transfer function for controller and plant : Transfer Fcn

•For Output : Use Scope

Figure 34: Simulink Model File for Demonstrating the Performance of the Designed Controller

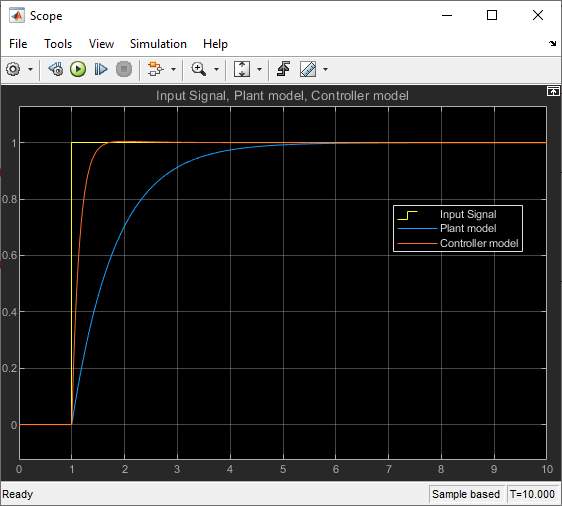

Step 3: Run Simulation and Open Scope for the results

Figure 35: Simulation Results Illustrating the Performance of the Designed Controller in the Simulink Model

The Figure 35 graph illustrates the impact of utilizing a feedback controller on system performance in relation to the simulation results of the plant model. It is worth highlighting that we can leverage a feedback controller to enhance system performance while keeping the plant model unchanged. The closed-loop response captures the behavior of the system's output concerning input commands or disturbances. Through a direct comparison between the controller's response and the simulation of the plant model, we can evaluate the controller's efficacy in attaining the intended control objectives without any alterations to the plant model itself. The ultimate aim is to minimize overshoot, hasten settling time, ensure stability, and achieve precise set-point tracking. A situation where the controller's performance surpasses the expectations set by the plant model simulation signifies a well-executed design characterized by enhanced dynamic attributes.